Eco-friendly fabric dyeing is an increasingly important topic that deserves the attention of both manufacturers and consumers. The use of natural and environmentally friendly dyes brings many benefits for the environment and human health. Since we sometimes encounter feedback about the fading of our barefoot colors, we decided to write this article explaining the differences between organic dyeing and conventional methods, and why it is important to choose environmentally friendly alternatives. Colors that don't fade and stay almost the same for years may seem like a great feature at first glance, but... it comes at a heavy price.

What is REACH and how does it affect your shoes and clothes?

Before we dive into the details, it's important to understand what REACH is and why it's so important to us. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is a European Union regulation that applies to all chemicals manufactured and marketed in the EU. REACH was adopted in 2006 and aims to protect human health and the environment from the risks associated with chemicals. It also aims to promote innovation and competitiveness in the European chemical industry.

REACH applies to a wide range of sectors, including textiles, footwear, cosmetics, electronics and many others. All chemical manufacturers and importers in the EU must comply with strict standards on the registration, evaluation, authorization and restriction of chemicals. This means that all substances used in the manufacture of our barefoot sneakers, including dyes, must be certified and meet high safety standards. Our dyes are therefore not only environmentally friendly, but also safe for you, our customers.

.png)

Source: Canva gallery

Why was REACH created?

REACH was created in response to growing concerns about the safety of chemicals commonly used in industry and consumer goods. Prior to REACH, chemicals were not adequately regulated in the EU and many posed serious risks to human health and the environment. REACH therefore set up a system to ensure that all chemicals are thoroughly evaluated and their use is restricted if they pose unacceptable risks.

One of the main objectives of REACH is also to ensure transparency and availability of information on chemicals. Manufacturers and importers must provide detailed information on the chemicals they use and this information must be available to both consumers and regulators. This enables better control and management of the risks associated with chemicals and ensures that goods manufactured in the EU are safe.

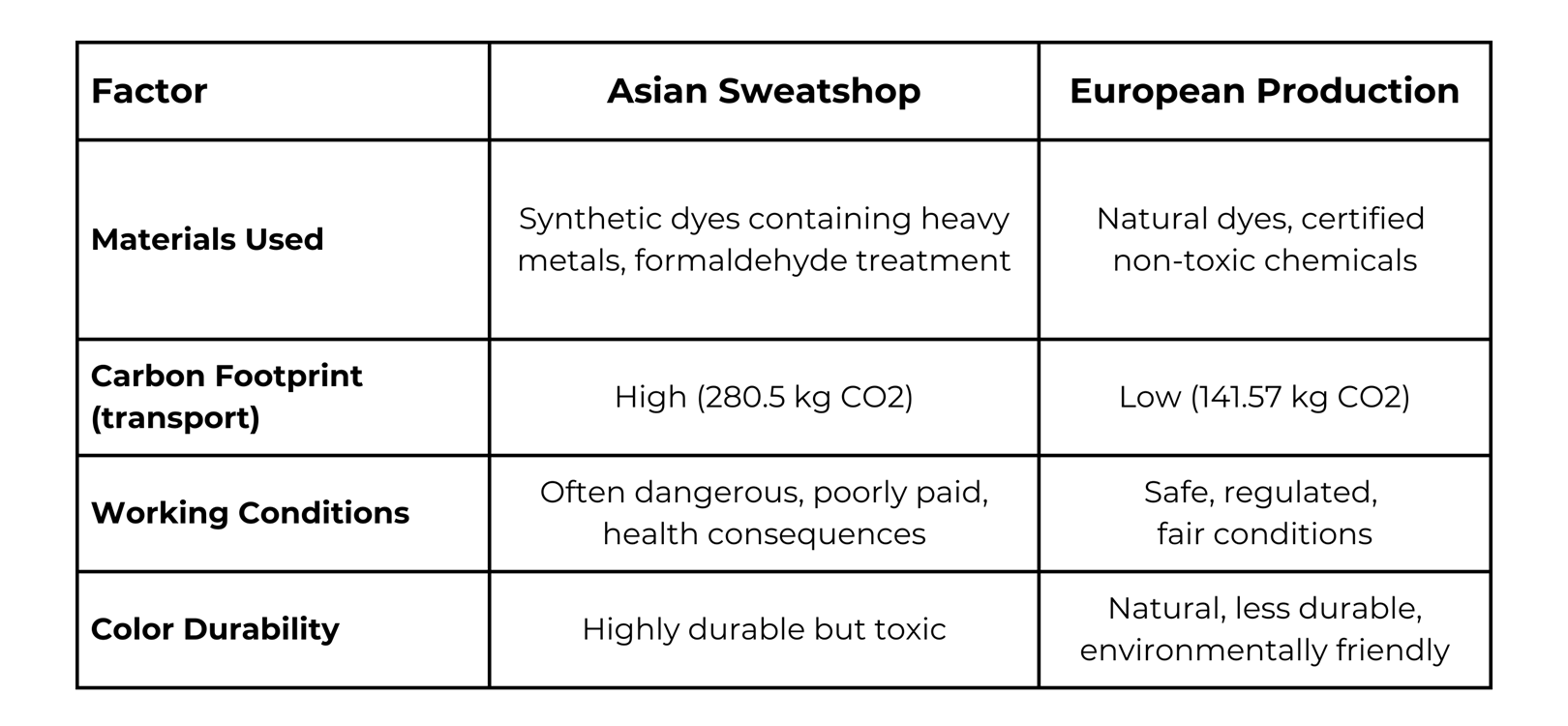

So now we know that shoes made in the European Union are subject to strict controls and rules, particularly when it comes to the use of chemicals and materials. But what about shoes and clothing that are manufactured in Asia, for example? To better illustrate this, we have prepared a journey of goods from Asia and a journey of goods produced in the EU to compare not only their environmental impact.

Source: Canva gallery

The story of goods from the Asian sweatshop

In Asian sweatshops, chemicals are used not only for dyeing, but also for bonding and strengthening materials. These chemicals are often very aggressive and toxic. To ensure the durability of the dye, synthetic dyes are commonly used, which are stable and long lasting, but have significant negative impacts on the health of the workers, the environment and consequently on the future owners who wear them.

In addition, to ensure that the goods arrive in a spotless condition after their long journey to Europe, they are often treated with formaldehyde. The goods are then loaded into containers and transported halfway around the world, which contributes significantly to their carbon footprint. And because these goods were not manufactured in the European Union, they are not subject to the same rules as those that are.

Did you know that...

Blackdye is often the most problematic in synthetics? The chemicals used to reach this color, like tar, are very toxic. These substances contain polycyclic aromatic hydrocarbons (PAHs), which are carcinogenic and can cause genetic mutations. For example, a 2009 study published in the journal Environmental Science & Technology found that workers exposed to PAHs in the production of black textiles had an increased risk of lung cancer.

Formaldehyde is commonly used as a preservative in goods made in sweatshops to prevent mold growth during long transport? This substance, however, is known for its negative health effects, including allergic reactions and potential carcinogenic effects. In 2010, a study published in the journal Contact Dermatitis found that formaldehyde in textiles and footwear can cause serious skin allergies. In addition, formaldehyde is also used as a non-wrinkling treatment for textiles during shipping.

If you buy goods that got to you via the route described above, you should wash them at least three times before wearing them for the first time? Otherwise, you are putting yourself at risk of an allergic reaction. Skin allergies are not rare in people who have worn newly bought clothes without washing them sufficiently.

Source: Canva gallery

The story of goods made in Europe

Bohempia's Barefoot sneakers are manufactured in accordance with REACH, which means we only use certified, non-toxic and environmentally friendly dyes. Therefore, goods made in the EU not only have a lower carbon footprint, thanks to shorter transport distances, but also guarantee that the workers who make them work in safe and fair conditions.

Our barefoot shoes are created in a carbon neutral process, and it goes without saying that we are sustainable and environmentally friendly in our production. This is reflected in our dyeing methods as well. Eco-friendly dyes are not as durable as chemical ones, but let's consider the fact that we wear our shoes outdoors where they are exposed to weather, sun and other elements.

Carbon footprint comparison: importing good from Asia vs. EU

To get a better idea of the difference in the carbon footprint between importing shoes from Asia and Europe, we can do a model calculation. Let's assume that shoes are imported from China (Shanghai) and from the Romanian city of Drăgășani, where our manufacturer is based, to Prague.

Import from Romania

- Transport: Mercedes-Benz Actros truck

- Distance: 1,231 km

- CO2 emissions: 0.115 kg CO2 per km (average emissions for this type of vehicle)

- Calculation: 1,231 km * 0.115 kg CO2/km = 141.57 kg CO2

Import from China

- Transport: Container ship (20,000 TEU, average CO2 emission 10 g/TEU-km)

- Distance: 20,000 km (Shanghai - Hamburg)

- CO2 emissions: 10 g/TEU-km

- Calculation: 20,000 km * 10 g/TEU-km = 200 kg CO2 (per container)

Subsequent transport from Hamburg to Prague (700 km by truck):

- CO2 emissions: 700 km * 0.115 kg CO2/km = 80.5 kg CO2

- Total CO2 emissions for import from China: 200 kg + 80.5 kg = 280.5 kg CO2

Comparison:

- Import from Romania: 141.57 kg CO2

- Import from China: 280.5 kg CO2

- Conclusion: Importing shoes from Asia produces almost double the amount of CO2 emissions compared to importing from Europe.

Comparison: Barefoot shoes from an Asian sweatshop vs. barefoot shoes made in EU

Our barefoot shoes may fade a bit over time, but we believe that this slight aesthetic wear is outweighed by the fact that you are wearing a product that is kind to the environment, your health, and was made under fair working conditions. So, take an interest in the story, the journey—not just of your barefoot shoes. It matters. For you, for the environment, for all of us.

For more information on this topic, visit these links:

.svg)